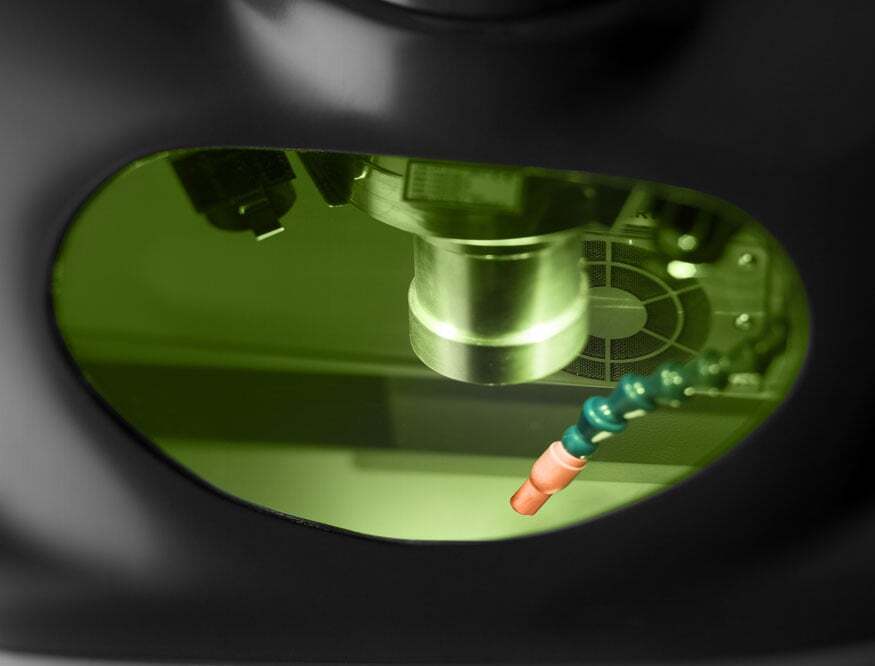

One of the main advantages of laser welding is its great versatility. This technology, in fact, can be used for a wide range of different applications and allows to treat different metal materials, therefore it can be used in many areas of the industrial world, always guaranteeing satisfactory results from the point of view of solidity, speed and precision.

Metals that can be laser welded

Laser technology allows you to weld a wide range of metals, and is due to some of the specific characteristics of the laser, namely:

- Possibility of adjusting the power of the beam, using higher or lower powers depending on the type of material treated

- Possibility of modulating the heat input, increasing or decreasing the size of the laser spot, that is, the surface of the material on which the beam acts

The laser, properly calibrated and adjusted, is therefore able to act effectively on the metal, but to obtain an impeccable final result it is important to be able to use the instrument at your disposal in the best possible way, correctly evaluating the type of power to be used and the amplitude of the shot on the basis of the processing that is being completed.

Laser welding: in which fields it is a winning choice

The laser is an extremely versatile tool, and it is for this reason that it can be used in a large number of different industrial fields, possibly also in combination with other welding systems.

In general, laser welding is an excellent choice in all cases where it is necessary to carry out interventions that require precision: a laser welding machine in fact allows you to take advantage of the advantages guaranteed by the presence of a very small laser spot and the possibility of adjusting the energy of the beam, and allows to obtain extremely pleasing welds from an aesthetic point of view.

There are so many areas in which this technology can be applied: in addition to the world of goldsmithing, the laser is perfect for carrying out interventions on accessories for the automotive or aerospace sector, but it can also be successfully used in the electrical and sensors sectors, as well as in the medical and dental fields. In the latter sector, in particular, the use of lasers has caused a real revolution over the years, pushing the world of orthodontics to renew its materials and techniques and allowing to obtain results that would have been unattainable using tools. traditional.

In addition, we must not forget that the laser is ideal, as well as in the actual production, also in the research and development phase of new products: with the laser it is possible to create prototypes with particular characteristics (for example by welding on very small areas) or by intervening on particularly thin or fragile objects), on which to carry out tests in view of a large-scale production. The laser, therefore, is ideal for use also in laboratories and research centers, as well as in the industrial sector.

Elettrolaser: our proposals for the industry

Elettrolaser offers a range of machines designed specifically for industrial applications, in particular for the repair of molds and dies:

Combo 200: this machine, ideal for use in large and small mechanical workshops, allows you to perform a wide range of welding and repairs. It is equipped with a mechanical arm that can be moved manually and that allows the operator to carry out, without any effort, interventions on molds of even large dimensions. The main advantage of this tool is its great simplicity of use, which is combined with the ability to adjust the power very precisely.

Combo 200: this machine, ideal for use in large and small mechanical workshops, allows you to perform a wide range of welding and repairs. It is equipped with a mechanical arm that can be moved manually and that allows the operator to carry out, without any effort, interventions on molds of even large dimensions. The main advantage of this tool is its great simplicity of use, which is combined with the ability to adjust the power very precisely.- DL 200: this laser welding machin

e is able to act in positions difficult to reach and on circular or inclined surfaces. These performances are made possible by the presence of 3 motorized arms which can be moved by joystick and which guarantee the precision of the movement.

e is able to act in positions difficult to reach and on circular or inclined surfaces. These performances are made possible by the presence of 3 motorized arms which can be moved by joystick and which guarantee the precision of the movement. - AWL: this welding machine is characterized by a high leve

l of automation, and is ideal for the repair of small to medium sized objects. It is equipped with a motorized bench that thanks to a joystick it is possible to move it with micro-movements, allowing extremely accurate welding to be carried out. Here too, likethe DL 200, it is possible to have the AUTOMATIC version, to automate processes.

l of automation, and is ideal for the repair of small to medium sized objects. It is equipped with a motorized bench that thanks to a joystick it is possible to move it with micro-movements, allowing extremely accurate welding to be carried out. Here too, likethe DL 200, it is possible to have the AUTOMATIC version, to automate processes.