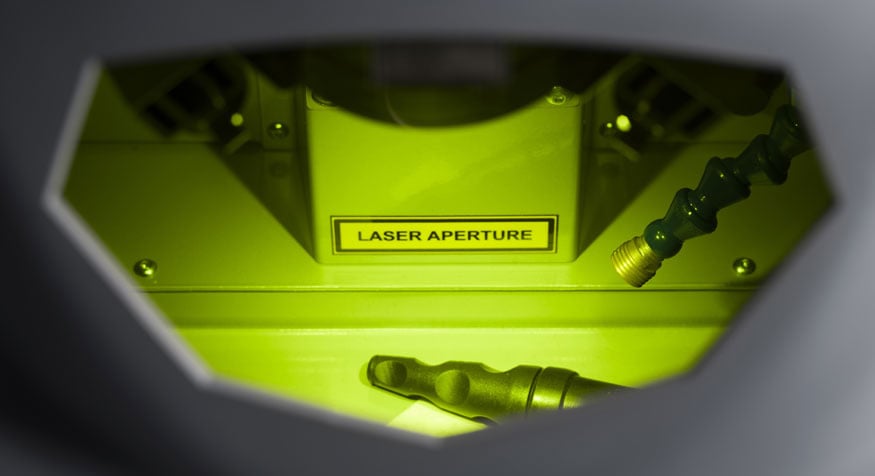

Laser Welding

Laser welding by Elettrolaser

The use of laser technology in welding represents an advanced and efficient solution to enhance production performance, both in industrial and artisanal settings.

Thanks to its precision and versatility, laser welding enables extremely high-quality results—often impossible to achieve with traditional methods.

Laser welding has been used since the 1960s in metalworking, especially in military applications. Today, after decades of technological evolution, it has become a well-established resource capable of adapting to a wide range of production environments.

Advantages

Choosing to use laser technology for welding operations allows highly accurate results in a very short time, meeting a wide range of needs in both artisanal and industrial settings.

Among the main advantages:

- Easy to use

- Extremely precise

- Reduced processing times

- Works on a wide variety of materials

- Safe: no thermal stress or deformation

- Energy-efficient and sustainable

%20(1)%20ref.jpg?width=598&height=598&name=orafo%20(2)%20(1)%20ref.jpg)

Applications

Laser welding is highly effective on a wide range of metals, including:

- Steel (including stainless steel)

- Aluminum

- Silver

- Gold

- Copper

- Bronze

- Nickel

- Titanium

- Platinum

- Palladium

Laser welding is widely used in industries such as jewelry, eyewear, sensor manufacturing, orthodontics, and all industrial sectors where precise, deformation-free joints are required—such as mold repair.

Our Products

DaDo DaDo 2.0

- Average power (Watts): 10

- Peak power (kWp) : 1,8 | 2,5

- Frequency (Hz): 1,5 - 4

Ms 3.5

VERSION 35J / 80J / 165J

- Average power (Watts): 30 | 30 | 75

- Peak power (kWp): 3 | 4 | 6,5

- Maximum energy (Joules): 35 | 80 | 165

- Frequency (Hz): 0,5 - 20

Master 4.0

- Average power (Watts): 80

- Peak power (kWp): 9

- Maximum energy (Joules): 225

- Frequency (Hz): 0,5 - 30

MEGA 5.0

- Average power (Watts): 90

- Peak power (kWp): 10

- Maximum energy (Joules): 245

- Frequency (Hz): 0,5 - 30 Hz

MEGA 6.0

- Average power (Watts): 100

- Peak power (kWp): 11

- Maximum energy (Joules): 255

- Frequency (Hz): 0,5 - 4

Mega 9.0

- Average power (Watts): 150

- Peak power (kWp): 15

- Maximum energy (Joules): 300

- Frequency (Hz): 0,5 - 50