Laser technology for engraving and marking fits in numerous applications and it has come such a long way that even some entry level machines would impress the most critical and demanding candidates. Speed, quality, and ease of use constantly progress, and users expect to have more for less. Here are examples of how the technology is implemented in Industrial production as well as the finest Jewellery pieces.

In industrial manufacturing laser engraving and laser marking are used to imprint logos, serial numbers, QR codes and micro text on stainless steel and a big range of metals.

In Jewellery the lasers allow users to customise, personalise, etch photos , cut pieces from sheet metal and work with precision metals with ease to create patterns on rings and add value to pieces.

When referring to the work of laser machines, we often use the terms "laser marking" and "laser engraving" interchangeably. However, engraving and marking are two different things, and both can be achieved with a laser engraver. The similarities and differences between these processes are discussed here:

- In marking, the laser beam hits the metal and only interacts with the surface but does not penetrate it. The laser parameters are typically gentle, and the energy transfer is set to make a mark on the surface without going deeper into the layers of it. There is minimal impact, and the part should not overheat. This controlled fusion process, followed by the natural cooling of the material, permanently changes the appearance of the struck surface, making a visible mark. By setting the laser appropriately, different aesthetic effects can be achieved as the user desires and as required for the job. Typical marking jobs would include techniques to create a colour effect, shading effects and photo etching.

- In engraving, the laser hits the metal with greater impact in order to penetrate the surface and modify it from the solid state to that of steam. There is therefore an effective removal of a small amount of metal, which not only changes appearance but is vaporized and taken away from the engraved object. To achieve this result, the laser must have the power and capacity to pierce through the engraved surface and create the desired effect that is deeper and more permanent than marking on the surface.

When referring to these types of work, people often use the terms "laser marking" and "laser engraving" interchangeably, considering them to be synonyms. However, engraving and marking are two different types of work, although both can be successfully used to imprint indelible signs on metal surfaces. Let's see what are the main differences that allow us to distinguish these two industrial processes:

Laser Marking vs Engraving, Here are the Differences

The marking and engraving performed through laser differ in the calibration of the ray used in the process, which produces different effects on the area affected by the shot:

- When a marking is made, the laser beam hits the metal, transferring an amount of energy sufficient to melt the superficial layers of the area affected by the shot, without overheating the surrounding area. This controlled fusion process, followed by a new cooling of the material, permanently changes the appearance of the struck surface, which is visibly different from the adjacent parts. By calibrating the laser appropriately, different aesthetic results can be achieved, such as markings of various colors or shading effects used for the realization of photo engravings.

- When an engraving is made using laser, the metal hit by the beam undergoes a process of sublimation and directly passes from the solid state to that of steam. There is therefore an effective elimination of a small amount of metal, which not only changes appearance but is definitively vaporized and removed from the engraved object. To achieve this result, the laser must be able to penetrate deeply into the struck surface, in order to cause the sublimation of the most superficial metal layers.

The processes of engraving and marking are, therefore, profoundly different, although both are carried out using laser equipment. To obtain an engraving it is necessary to set the machine in such a way as to reach a concentration of energy sufficient to trigger the process of metal sublimation, therefore carrying out an engraving job requires the use of a greater amount of energy compared to a marking process. In the later, it is sufficient for the laser to transfer an amount of energy just sufficient for triggering the fusion process, at a lower power.

There are however, some characteristics that both processes share. Both, for example, cause a permanent modification of the affected area, and that is why marking, despite requiring a lower energy expenditure, is widely used in the industrial sector. This method allows adding detail and information to components at the end of the production process using minimum amount of energy while creating a permanent mark. It’s a versatile cost-effective solution for small volume up to high production with automation features available with various machines.

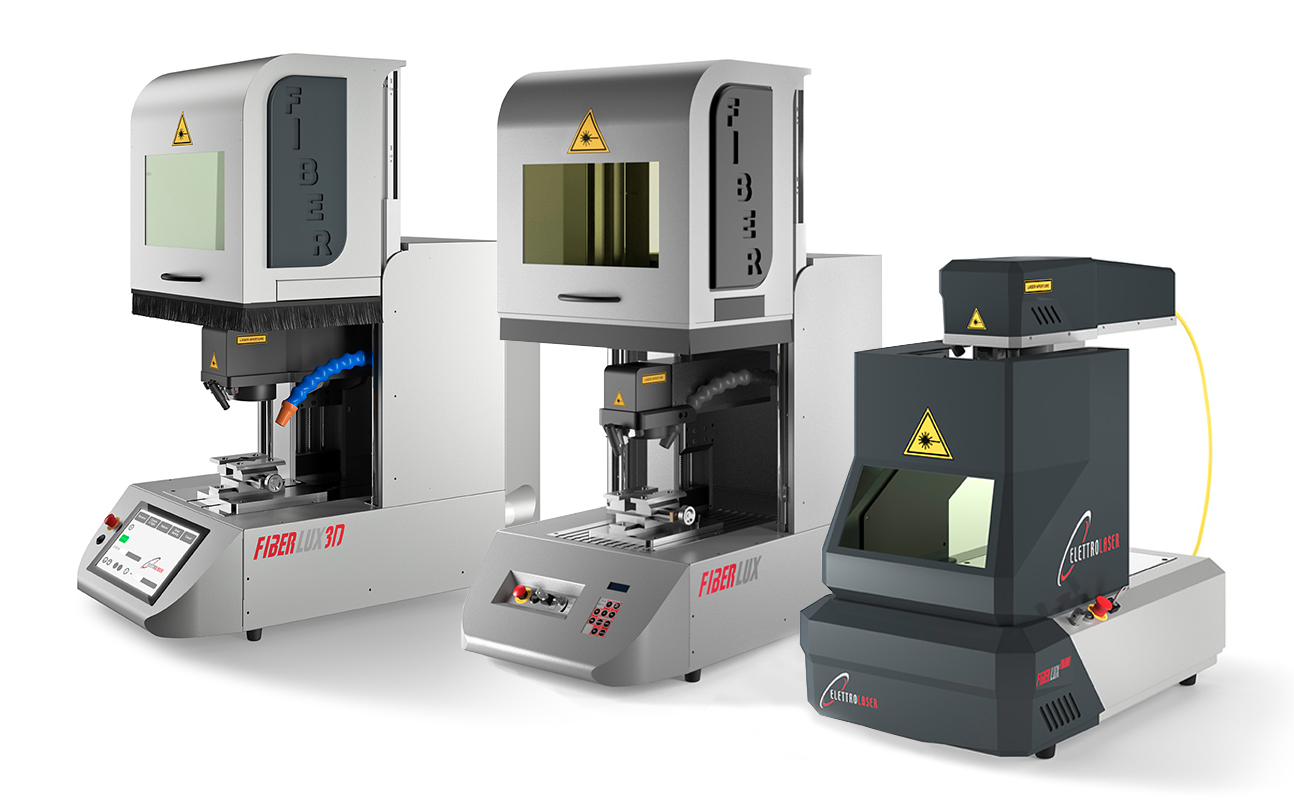

Elettrolaser provides the market with a wide range of laser marking and engraving equipment to serve industrial sectors, but attention is also given to develop solutions for small and medium-sized companies and their needs. The manufacturer also offers laser equipment that meets the demanding needs of those precision engineering companies, as well as heavy duty tools for large scale and heavy-duty objects.

To learn more about the Elettrolaser engravers & markers, browse our catalog and contact our consultants who will be happy to answer any questions you may have!