Fiber laser engraving and cutting, how it works

With the laser you can weld, you can engrave, mark and cut.

In our activity we deal with studying and manufacturing machines with Laser technology, to be used in the sectors of industry, jewelery and in the dental field.

The mission of our company is to help customers find their own solution, which can satisfy particular processing needs.

We do this also by explaining the functionality of each machine and each specification, based on the reference context.

For example, how does laser engraving work?

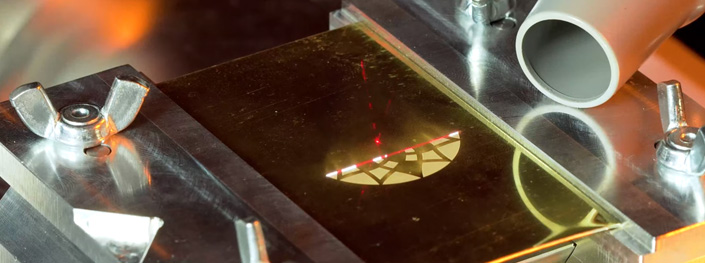

- In laser engraving, the material is struck by the incident laser beam which, depending on the exposure time, changes color and creates a contrast or material removal takes place, which is however recovered through the suction and recovery system provided.

The resulting laser engraving is permanent and very resistant to abrasion. - The laser beam is obtained through the amplification of light by absorption and energy radiation. The resonator element is made up of glass fibers which, when pumped with diodes, generate the laser beam with a very small wavelength, ie 1064 nm.

The laser allows the engraving of accurate details, is not subject to wear and thus allows the maintenance of precision during the entire marking process.

The focal diameter of the laser engraver is very small, but it has a very high intensity: for this reason the fiber laser technology is the best when it comes to marking very hard or plastic metals.

Fiber laser engraving

When a technician uses a laser engraver he must basically:

- Sit at a computer

- Create the engraving layout in the graphics program he normally uses (CorelDraw, Photoshop, AutoCAD, Illustrator, InkScape, Autocad, etc.)

- Send the graphics to the software or import the images in JPEG, PNG, TIFF, etc.

- Set up the engraving and cutting applications using the supplied software included with our markers

- Send the graphics to the laser

With Elettrolaser’s engraving machines is possible to engrave on any precious material (gold, silver, etc.), steel, aluminum, plastic and much more.

Laser cutting is another possible process: how does it work?

It is based on the removal of material from a surface that, by causing a sharp division, cuts the surface in two following a line designed on the computer.

The laser cutting machines are able to separate the material even on multiple layers, thanks to the strong induction of heat generated by the laser beam.

When considering the material to be cut, the parameters of use change.

The density of the material, its hardness, its composition are important factors because cutting can require more energy.

The markets of reference for our markers are the goldsmith and the industry.

Need more information on cutting and engraving?

We invite you to watch this video:

...and follow us on YouTube!

Here are some examples in the gold sector:

Here are some examples in the industry sector: