Elettrolaser: development, professionalism, and quality to look towards the future of the laser industry.

Elettrolaser is a young and innovative company, strongly oriented towards the future. Since 2007, it has achieved many significant milestones and continues to work tirelessly towards product development and customer offerings.

One key factor contributing to its success is the commitment to constantly update its production, providing increasingly high-performance and user-friendly solutions in the market. These solutions cater to a wide range of production environments, from small artisan workshops to large-scale structured companies, enabling efficient operations and impeccable quality results. In addition, Elettrolaser excels in offering a truly comprehensive service. It goes beyond supplying laser welders and markers by providing customized products and ongoing customer support and assistance.

To trace the growth of this company and explore its development prospects, we have asked some questions to Elettrolaser's CEO, Massimo Grigoli, who shares insights into the company's past and future.

Let's start with the origins: How was Elettrolaser founded?

Elettrolaser was established in 2007 when Elisa Montresor, Guerrino Ferrarini, and I decided to leverage our personal, technical, commercial, and administrative skills and expertise to build a new venture specializing in the technologically advanced field of lasers. We chose to embark on this adventure because we felt a strong drive towards entrepreneurship. We wanted to test ourselves in a context that we could call our own, where we would have the opportunity to choose, experiment, and be proactive. We desired ownership over our time and future, and the industrial field we selected seemed to offer great opportunities.

I must say that we are extremely satisfied with what we have built to date. To be honest, if someone had asked me at the founding of Elettrolaser to predict the company's growth, I probably wouldn't have dared to hope that fifteen years later, we would become the reality we are now.

Which laser models did you initially invest in, and how did you expand your product catalog and customer base?

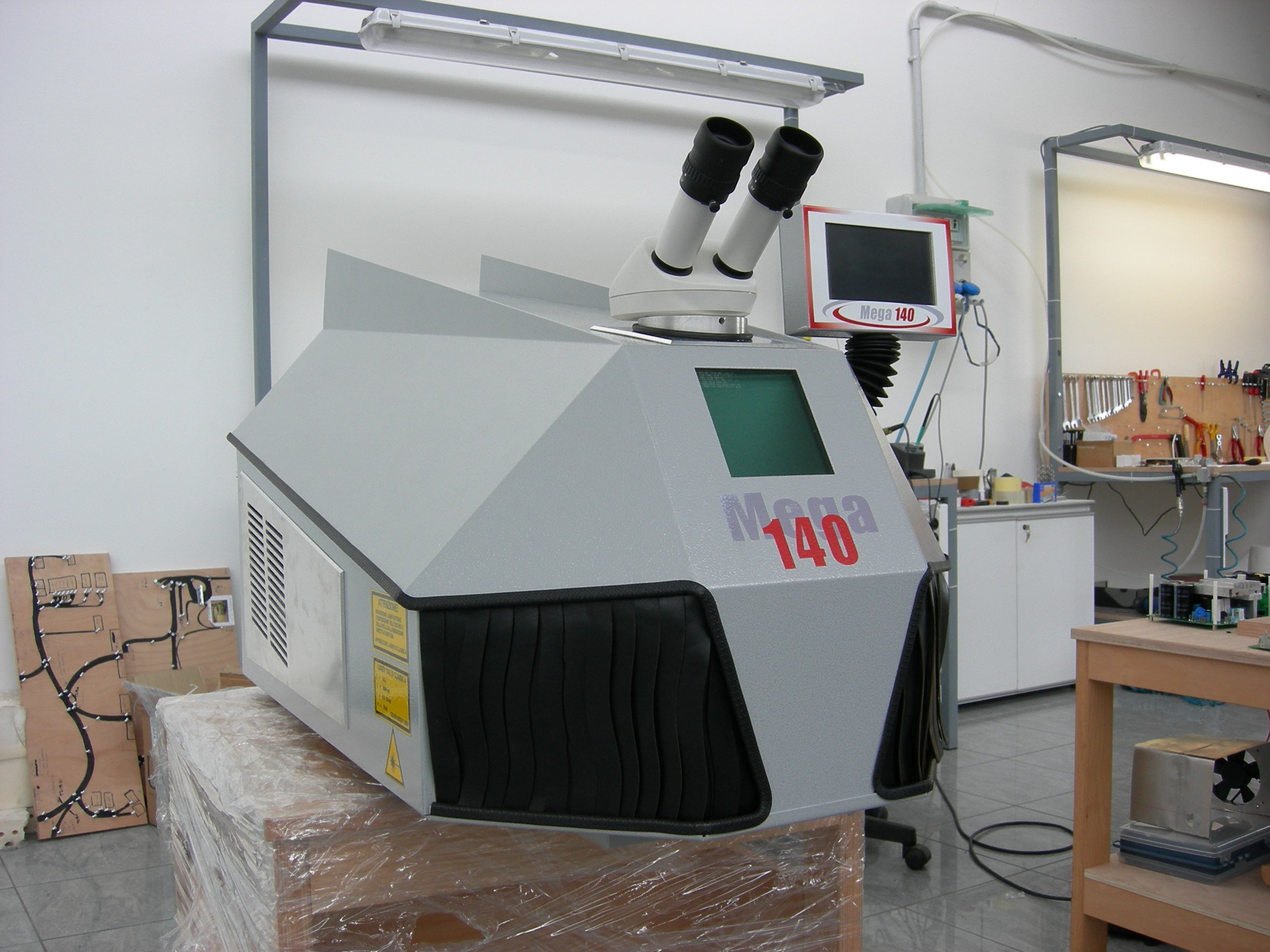

When Elettrolaser was established, we initially focused on producing welders, and the markers entered the scene a little later. Our first welder was the MEGA 140, named after the acronym formed by the initials of our names—Massimo, Elisa, and Guerrino. It reflected our significant investment, both personal and professional, in this product. This choice brought us good fortune, and to this day, we still have the MEGA series welders in our catalog, of course, improved and updated compared to the original model.

We then began working in two directions. Firstly, we made great efforts to participate in the most important industry trade fairs, aiming to establish our brand and promote our name. Simultaneously, we expanded our product catalog. In this regard, a turning point was the development of the MASTER 100 welder, a smaller and more affordable model than the MEGA, which allowed us to reach customers who would not have otherwise considered owning one of our lasers.

This expansion of the catalog and customer base gave us the opportunity to grow significantly, not only in terms of revenue but especially in terms of specialization. We welcomed highly skilled professionals, mechanical and electronic designers, into our company, strengthening our research and development department. Similarly, our sales department expanded, and we had dedicated personnel who made a significant difference in developing relationships with customers. Gradually, we were able to offer customers increasingly advanced and customized technological tools, further strengthening and growing the company. A satisfied customer is the best guarantee of success for any business.

This growth would not have been possible without our ability to evolve towards greater managerialization. Today, each department has its representative, and the company can grow in a coordinated manner because the objectives and corporate strategy are clear and shared, with everyone working towards the same direction.

Regarding this, what are the key points of Elettrolaser's strategy? What does the future hold?

Naturally, the core of our commitment is always to provide customers with machines of excellent quality. This means investing significantly in the search for reliable raw materials and continuous product updates, while emphasizing the importance of post-sales support and assistance. Based on this foundation, which applies to all the lasers we have produced, produce, and will produce, our strategy focuses on developing machines that meet the needs of specific market niches. For us, being innovative means precisely that: being able to offer a solution that didn't exist before or was inaccessible to a particular segment of the target market. This is what we achieved with the DADO welder (https://www.dadowelder.com/it/). Thanks to its compactness, unique design, and affordable price, it managed to cater to the needs of customers who would otherwise struggle to enter the world of lasers. This approach allows us to offer lasers that meet highly specific needs, providing customers with what they require in any circumstance. To achieve this, we have recently made significant investments in M&E, enabling us to produce lasers capable of achieving exceptionally high performance in terms of power, speed, and size much faster. Working in this way naturally requires substantial investments in R&D. Offering effective solutions to specific needs demands intelligence, creativity, and in-depth knowledge of the industry. However, we believe that this is the right path to continue growing over time, constantly renewing ourselves, and maintaining the ability to understand, interpret, and anticipate our customers' desires.

If you want to learn more about the features of our lasers and discover what Elettrolaser can offer you, our technicians are available at any time.