Elettrolaser has always been committed to offering its customers laser systems designed to be precise, efficient, and capable of delivering impeccable performance while minimizing energy consumption and waste.

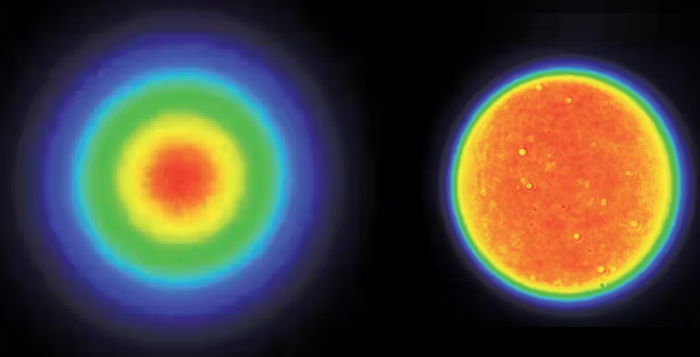

To this end, alongside the Smooth Spot technology already featured in many of our laser welders, we have developed a new type of pulse: SMSP. This innovation further enhances the quality of the emitted laser beam, ensuring particularly shiny and durable welds with reduced power consumption.

What Is SMSP Technology and What Are Its Applications?

The Smooth Spot technology — standard since 2020 in Elettrolaser’s Mega-Silver and Master-S 130 J welders — enables precise control over the shot diameter and produces a laser beam that is precise, smooth, and homogenous. This guarantees outstanding results in terms of welding precision and uniformity.

-3.png?width=310&height=438&name=Master4-3%20(1)-3.png)

The SMSP pulse operates at low current levels and delivers energy in a smooth but steady manner. This significantly reduces overheating of the worked surface, focusing energy precisely on the firing point and avoiding dispersion. As a result, it enables extremely precise, shiny welds without burnt edges, while maintaining a consistent pulse rate—even when operating at high frequencies.

Applications of SMSP Technology

Thanks to its unique characteristics, SMSP technology is particularly suited for:

- Welding filigree or hollow chains: These delicate items are at risk of damage from excessive heat and require the use of a particularly soft laser beam.

- Overlay welding with filler wire: The ability to precisely control the shot diameter and minimize burns along the edges makes SMSP ideal for this process.

- Polishing: The softer laser beam minimizes the “burnt” effect, achieving highly satisfying results in terms of brightness and shine.

All the Advantages of SMSP Technology

The characteristics of the laser beam produced using SMSP technology provide numerous benefits, improving weld quality while making operations more efficient and environmentally sustainable. This technology requires less electrical power from the grid, immediately reducing energy consumption, while simultaneously limiting lamp wear and extending its lifespan.

Using laser welders equipped with SMSP pulses allows you to:

- Reduce the heating of the welded object, thanks to a less aggressive laser beam.

- Achieve particularly shiny welds, with precise control over the energy delivered, avoiding burn effects.

- Enhance the energy efficiency of the welder, as the precision of the beam ensures strong welds with lower energy consumption.

- Lower electrical consumption by approximately 20%, leading to immediate reductions in energy costs.

- Extend lamp lifespan by up to 20%, due to reduced electrical current usage.

- Enable higher laser frequencies, with an estimated increase of about 20%.

Thanks to SMSP technology, Elettrolaser welders are less energy-intensive, more efficient, and deliver enhanced performance. With identical results in terms of weld strength and reliability, they consume less energy while achieving even better surface quality and shine.

To learn more about SMSP technology and the welder models featuring this new pulse as standard, contact our team!