Fiberlux NANO, a quality entry level for laser cutting and laser engraving on all precious metals

The laser technology in the gold and the industrial sector in recent years is having more and more success, thanks mainly to its main features, such as more precise incision, the increased speed of execution and the low cost of maintenance.

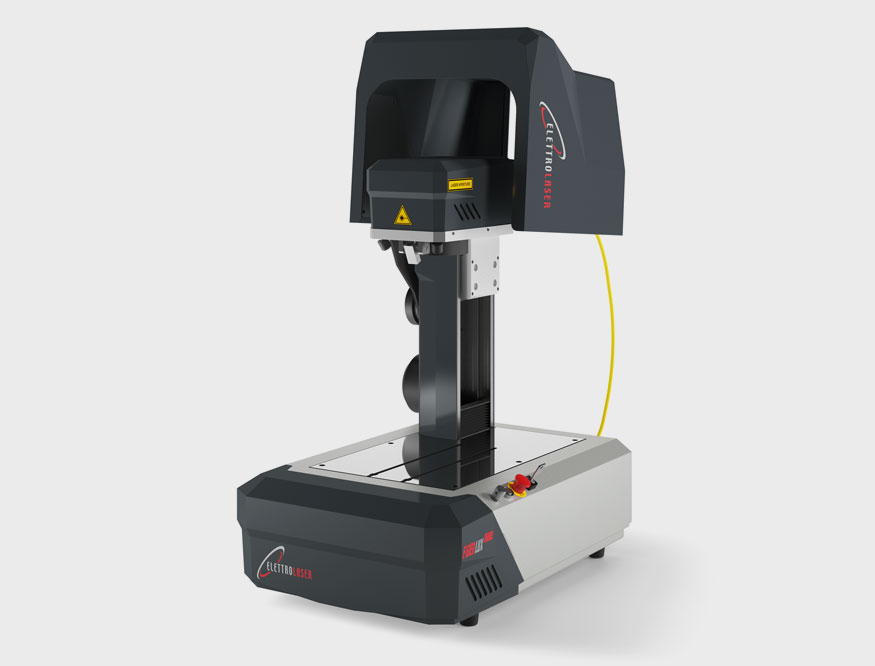

Elettrolaser with Fiberlux NANO wanted to satisfy the growing demand from small goldsmith laboratories and create a compact laser marker at an affordable price.

With the 'mini’ model by Elettrolaser, which is developed by incorporating the research and innovations of the FiberLUX EL and FiberLUX PRO series, it is possible to perform cutting and engraving operations on all precious metals, but also on steel, aluminum, titanium, special alloys and much more.

It is also equipped with a laser source in ytterbium-doped fiber optics and is a machine with low environmental impact and low maintenance.

| APPLICATIONS |

It allows to engrave objects of any metal (gold, silver, steel etc.), in particular logos, brands, photo-engraving, texts, graphic designs and, using the high precision rotary axis system, the inside and the outside of rings (this one provided as an accessory).

With a maximum marking area of 160x160 mm and with resolutions up to 20 μm.

| POWERS AND MAIN FEATURES | |

| 30 W | 60 W |

Space-saving, it offers a working room that is completely accessible thanks to the removable protective cover.

It is equipped with the innovative "user-friendly" focusing system with overlapping pointers, through the manual adjustment of the "Z" axis, and can be supplied with a camera for the working area, this for an optimization of the processing or for any remote assistance.

FiberLUX NANO is supplied complete with SOFTWARE, easy and intuitive, capable of importing files from the most well-known computer-design programs currently in existence (svg, dxf, bmp, plt, jpg, dwg, etc.).

Also available in the SPECIAL VERSION for trademarks with which it is possible to affix the title based on the new reference protocol for the laser marking of precious metals and proceed to electronic punching through a simple USB token.

| OPTIONAL AVAILABLE |

- X & Y clamp, for fixing and positioning the pieces;

- Rotary axis system (for engraving inside and outside the rings and more);

- Internal camera;

- Dust aspirator (to optimize the cleaning of the machine and the work area);

| WHY CHOOSING FIBERLUX NANO |

Ideal solution for small/medium laboratories, to complete processing lines and for those who for the first time face the world of laser engraving and cutting.

| FIBERLUX NANO 30 | FIBERLUX NANO 60 | |

| OUTPUT POWER | 30 W | 60 W |

| WAVE LENGHT | 1064 nm | |

| M2 | < 1,8 | |

| POWER SUPPLY | 230 V 50/60 Hz (opt. 110 on request) - 1 kW | |

| WORKING SPACE DIMENSION (LXDXH) | 250x250x310 mm | |

| WEIGHT | 35 kg | 35 kg |

| FOCAL 100: MARKING AREA / SPOT | 60x60 mm / 16 um | |

| FOCAL 160: MARKING AREA / SPOT | 100x100 mm / 26 um | |

| SPEED OF GALVO HEAD | 5000 mm/s | |

| MAX PULSE ENERGY | 1,5 mJ | |

| MAX FREQUENCY | 60 kHz | 4000 kHz |

| COOLING SYSTEM | air cooled | |

| PULSE DURATION | 10 - 100 ns | 2 - 500 ns |

| LASER CLASS | IV | |