Laser in jewelry industry: modify and repair jewels without removing the gems

Using lasers to carry out repair or restorative work on rings, necklaces, bracelets, chains and other jewelry made of precious materials is durable and aesthetically pleasing thanks to the specific

properties of this technology that allow you to make flawless welds.

In fact, repairing jewelry with a laser beam permit to reach all components of the jewelry, regardless

of position, shape or thickness, for all sorts of interventions. Lasers can therefore reach areas of the

jewel that are difficult to reach with other welding systems.

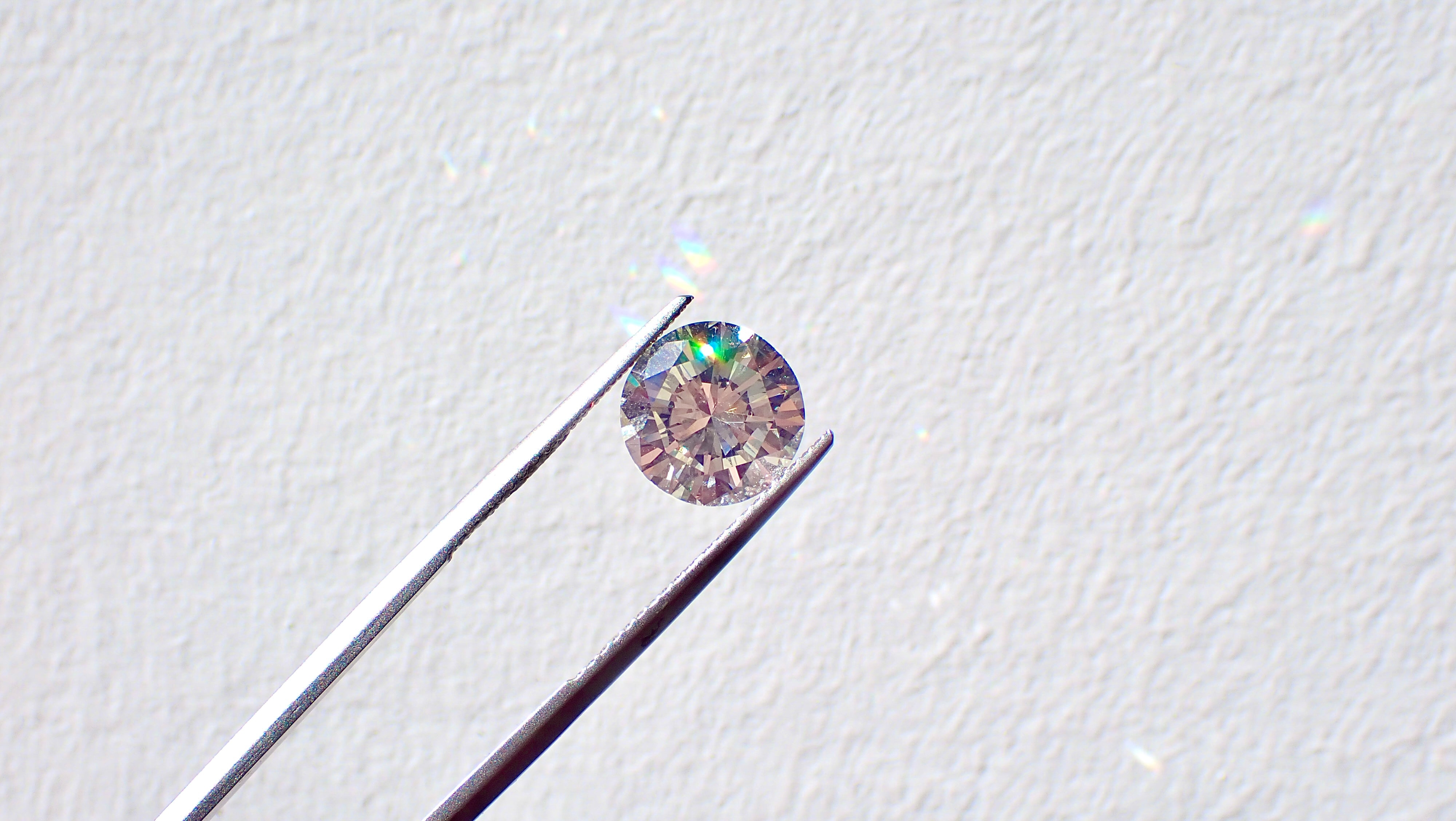

Additionally, lasers allow you to act very selectively on jewellery, as the beam's shot diameter is

very small and can be adapted to the specific needs of each intervention. In this way, the surface

that is heated and melted by the laser beam is very limited, allowing the creation of invisible welds

while avoiding possible damage to the gemstone.

Another advantage is the easy handling of the laser to reach each part of the jewel in a punctual and

safe manner that means the possibility to carry out welding operations without removing the gem

set in the jewel.

In fact, when working with traditional welding techniques such as micro-flaming, it may be necessary

to remove the gem from the jewel to avoid damaging it and to enjoy freedom of movement during

repair.

However, removing set stones is not a risk-free process. Even with the utmost care, there is always

the possibility of damaging the stone during removal. At worst, it can even happens to break stones.

Even if the procedure is carried out without damage, the process can take a considerable amount of

time, especially when removing many small gemstones.

For all these reasons, it is always better to avoid removing gems unless absolutely necessary. Lasers

have proven to be a great ally in this sense. In fact, laser welders can be easily adjusted in terms of

frequency, power and size of the focal diameter, so they can be very precisely positioned on the

specific location of the jewel you wish to treat. It can act on easily in close proximity to gemstones or

in hard-to-reach places.

For this reason, the use of lasers in the jewelry sector can significantly reduce processing

times. Laser welding itself is a very fast process and the use of lasers also avoids manual intervention

in series production such as not removing gems from their site, operation that can cause a significant

increase in intervention time.

To learn more about the advantages of lasers and all the models of welders that Elettrolaser has

developed for the jewelry world, please visit his website and contact us.