Solutions for engraving and cutting: all the features of a laser marking machine

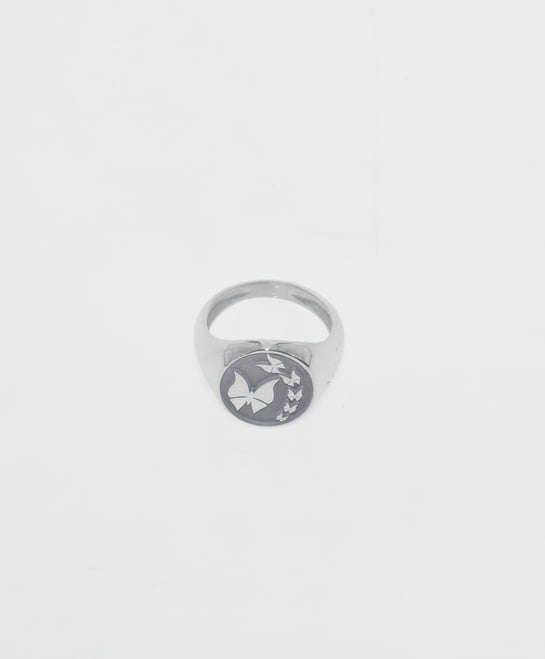

If you are looking for a tool that can cut and engrave quickly and accurately, a laser marker is the perfect solution for your needs. The laser, in fact, can be used not only to weld but also to remove metal, and allows to obtain impeccable results in a great variety of fields, from jewelry to all sectors of industrial production (remember, in this regard, that ISO quality standards require that every component used in industry must be traceable, and marking is essential to ensure this traceability).

.jpg?width=545&name=3D-Engraving%20(3).jpg)

How does a laser marking machine works

The engraving operations are normally carried out by removing small quantities of metal by scratching or by using tool pantographs. These techniques allow to obtain excellent results, but they require a significant use of time and are subject to some technical limitations, since particularly thin or delicate objects could be impossible to engrave, or suffer damage during processing.

The same type of activity can be done more effectively using a laser marking machine. This instrument, using laser technology, hits the metal to be treated by heating it intensely but extremely precisely. This allows you to act on very small portions of the object, obtaining engravings that are, at the same time, precise and extremely durable. With the same technique, by repeating the passage of the laser beam several times over a very small portion of the object, it is possible to obtain a cut. The laser can also be used on parts of the object that are difficult to reach or on uneven surfaces, without the need to heat the object in its entirety and thus ensuring that it is not damaged in any way during processing.

How to choose a laser marking machine

To choose a laser marker it is necessary to make an evaluation that takes into account:

- the type of work to be completed

- the quantity of pieces to be treated

- the materials to be engraved

If the number of pieces to be made per day is small, it is possible to move towards a compact and small-sized laser marker, capable of minimizing consumption and save space and still guaranteeing perfect results. A machine of this type is ideal for non-continuous processes, therefore for those looking for a marker to be used occasionally to make artisan-type engravings, not in series.

If, however, the production is of a semi-industrial type, it is necessary to equip oneself with more efficient and versatile tools, able to use different powers and to carry out the work quickly: this is the case, for example, of laser markers equipped with automatic drag and clamp device or those that use advanced software that allow you to obtain particular effects from an aesthetic point of view. In this case, the range of jobs that can be completed grows considerably, as does the number of pieces that can be processed per hour. Tools of this type, suitable for industrial production, are generally less intuitive to use, since they use complex software. For this reason, when choosing them it is essential to know that you can count on an efficient operator training service and technical assistance.

The Elettrolaser marking machine

Elettrolaser marking machines are able to satisfy any type of production requirement, and are suitable for both a small laboratory and an industrial plant. Here are the main models in our catalog:

- FiberLUX NANO: this marking machine is ideal for small productions, and is therefore the perfect tool for shops or workshops where occasional cutting or engraving work is required. It is practical to use both mechanically (it is equipped, for example, with a clamp to hold the piece you are working on) and at a software level, and a training day is amply sufficient to allow any operator to acquire all the necessary knowledge to use it without difficulty. The marking machine can be completed with a 10x zoom camera that allows you to frame and enlarge the work area, and can also be used with the cover open in case you have to work on relatively large pieces.

- FiberLUX EL: this model, equipped with an automatic drag and clamp device, can produce pieces in series, since its larger working base makes it suitable even for medium-intensive industrial production. It can be set on three different power levels, so depending on the machining you are carrying out it is possible to increase or decrease the cutting power or the execution speed. The installed software is simple and intuitive to use, and processing is quick also thanks to the technology that allows you to lift the head in a motorized way, reducing the time required for focusing.

- FiberLUX PRO: this marker is the top model on the market, and best summarizes efficiency and ease of use. It can be used with a wide range of powers (up to 200 Watts), is equipped by default with an integrated camera and software for inserting the trademark and can be completed with various add-ons, such as software for bas-reliefs. The machine is designed to operate quickly and is easy to use and customize: a touch screen allows you to communicate directly with the instrument and allows you to use it without going through the PC; moreover it is possible to save certain processes directly on the marking machine or on external memory supports that can be connected to it. The software it is equipped with is more dynamic, therefore more suitable for production, and can be integrated with the optional scanner detection, which allows the machine to automatically recognize the types of pieces present in the work area. Using a dongle, it is also possible to work remotely on the software while the machine is running, sharing files over the network.

This model is also available in the FiberLUX 3D variant, equipped with all the potential of the PRO model but also able to work on curved or rounded surfaces.

Find out more about the characteristics of our markers, compare their performance and contact us to ask for advice: we will be happy to answer all your questions!