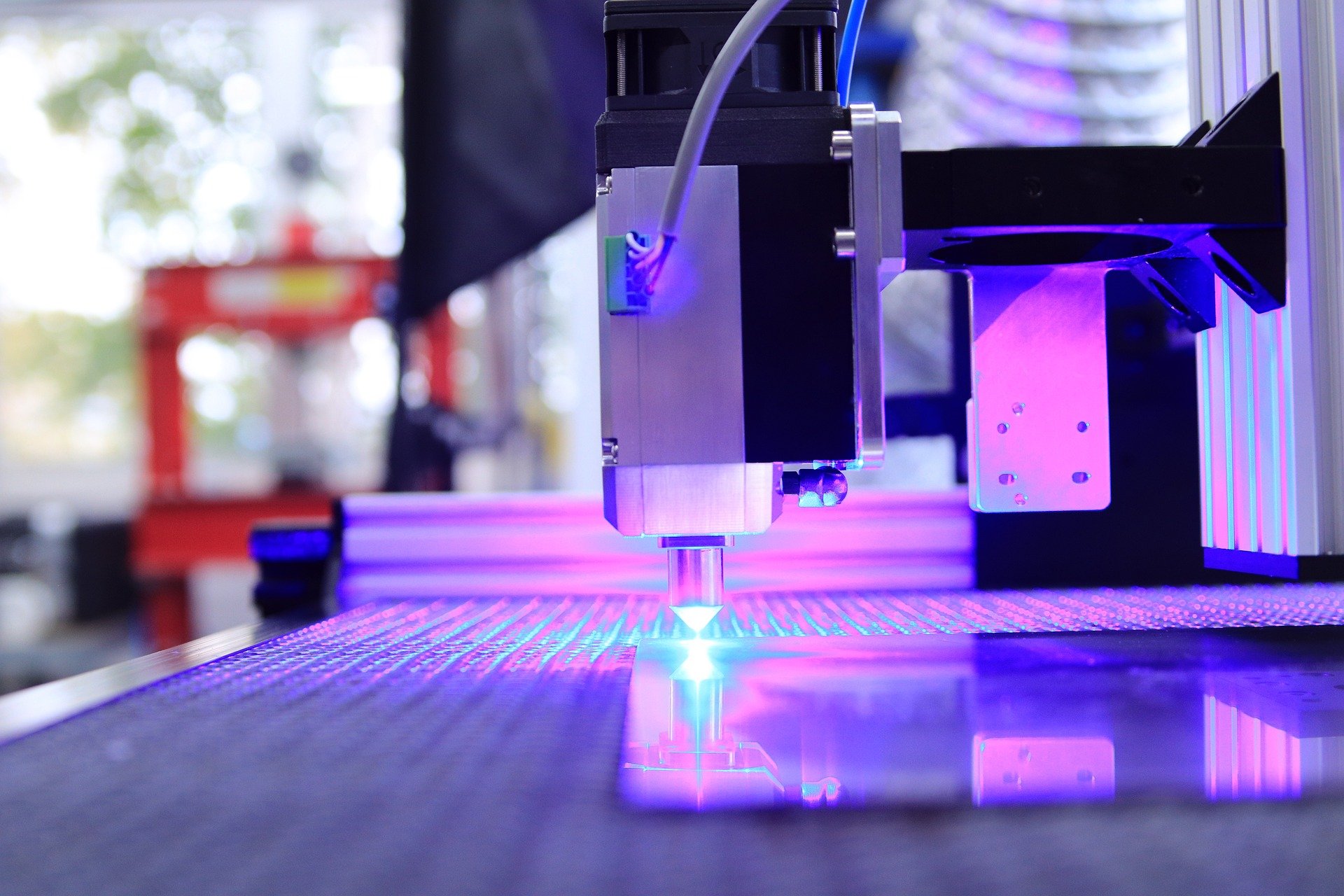

Laser marking is widely used in the jewelry industry, as well as in dentistry and various industrial sectors, thanks to the significant advantages it offers in terms of precision, speed, and accuracy of the results.

In these fields, lasers are commonly used to mark objects and components made of both precious and non-precious materials, such as gold, silver, platinum, steel, titanium, etc. However, laser technology's applications are not limited to metals alone. It can be used to mark various types of materials, including plastics, wood, leather, glass, ceramics, and many others.

To achieve this, it is necessary to equip oneself with suitable tools and take specific precautions in adjusting the marking machine's parameters. By doing so, impeccable results can be obtained, even on the most delicate materials, while taking advantage of all the benefits associated with using a high-performance and safe technology like laser.

Marking Plastic with Laser

One of the main advantages of laser marking is its ability to work on extremely small portions of the object to be engraved, avoiding overheating and preventing damage or deformations. This characteristic makes lasers highly efficient for processing various types of plastics, which can be successfully engraved using a properly configured laser marker.

When setting up a laser marker for plastic treatment, it is essential to consider the type of material being treated (as each type of plastic has different characteristics). Additionally, it's important to remember that, in general, plastic absorbs the laser to a much greater extent than metal due to its low reflectivity. This aspect significantly affects the power required to complete the process and its duration: marking plastic with laser requires much shorter times and extremely precise beam control. The FiberLUX fiber lasers from Elettrolaser allow achieving these results easily and safely, both on metal and plastic materials.

Why Choose Laser for Plastic Marking

Using lasers for marking metals offers many advantages that, to a large extent, also apply to plastic marking. Laser marking provides excellent results in terms of:

- Engraving precision: Laser marking allows for extremely accurate engravings, ensuring uniformity of results, not only aesthetically and functionally but also in terms of anti-counterfeiting efficiency.

- Durability: Laser marks are resistant to heat, light, and wear, and they do not degrade over time, even when exposed to chemical substances.

- Reduction of processing times and costs: Laser marking is a rapid and cost-effective process that does not require the use of inks or chemicals, nor preliminary preparations of the object.

- Flexibility: Laser marking allows for marking hidden or hard-to-reach points on the object, providing maximum flexibility for the user.

All these features make laser technology particularly suitable for a wide range of industrial applications, including engraving logos, serial numbers, or codes for component traceability.

Beyond Plastic: Laser Marking on Ceramics, Wood, and Other Organic Materials

Plastics are not the only non-metallic materials that can be effectively treated using laser technology. It is also possible to use lasers to mark organic materials such as wood, leather, fabric, ceramic, and even glass (although transparent, glass can be marked using a contrasting surface placed behind the layer to be engraved).

All these applications require careful calibration of the marking machine's parameters to avoid the risk of burning, melting, or otherwise damaging the objects to be marked. Overcoming this issue involves taking particular precautions: our first suggestion in this regard is to perform various engraving tests on samples of the material to be treated before proceeding with the actual processing. By starting with very low power settings and gradually adjusting the laser parameters, it is possible to identify the combination that guarantees the best result in terms of speed, precision, and product safety.

The ability to easily conduct such tests, without risking damage to the equipment and investing limited resources, is one of the great advantages associated with using laser technology for non-metallic materials processing.

Elettrolaser technicians are always available to provide advice to customers seeking more information on the correct setup of laser markers for plastic and organic materials processing.

To learn more about Elettrolaser's marking machines' performance and their potential applications, contact us!