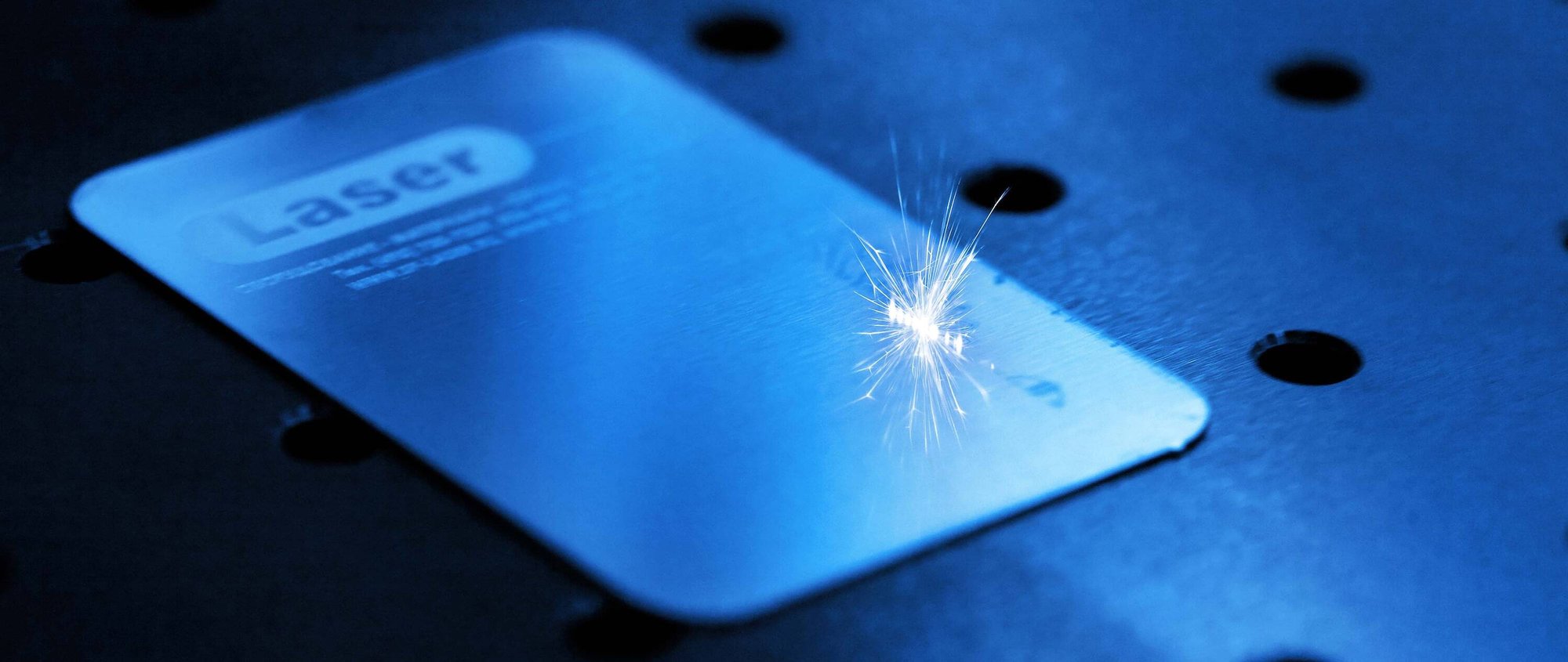

Laser marking and cutting

Solutions for industries and artisan workshops

Using laser technology for marking and cutting offers countless advantages in both industrial and artisanal contexts. This technology ensures outstanding performance in terms of speed, accuracy, and precision—results that are often impossible to achieve with traditional tools.

Now widely adopted across various production sectors, laser systems are increasingly accessible and versatile. They can meet the needs of small workshops as well as large-scale industrial plants processing thousands of pieces per hour. The key is choosing the right machine based on specific requirements, striking a balance between power, ease of use, and space availability.

Advantages

Using a laser for marking operations offers several key benefits:

- Versatility

- Precision

- Long-lasting results

- Speed

- Efficiency

- Ease of use

- Component traceability

Applications

Laser marking is used across many industries due to its precision, flexibility, and ability to work on a wide range of materials (precious metals, titanium, steel, plastics, etc.).

- Manufacturing industry (aerospace, automotive)

- Goldsmithing and jewelry

- Telecommunications

- Telecommunications

- Custom engravings

- Marking of codes and DataMatrix

- High-precision micro-cutting

- Photo-engraving on complex surfaces

Our Products

OPERA

VERSION 20W / 60W

- Type: Laser + CNC

- Laser power (Watts): 20 - 60

- Maximum marking area (mm): 100x100

- Maximum CNC area (mm): 200x140

FIBERLUX NANO

VERSION 30W / 60W

- Laser source: Fiber | MOPA

- Laser class: IV

- Z-axis: Manual

- Galvo Head Speed: 5000 mm/s

Luxmark S

- Laser source: Fiber | Green | UV

- Laser class: I

- Z-axis: Motorized

- Workpiece height: max 18 cm

Luxmark M & TOP

- Laser source: Fiber | Green | UV | CO2

- Laser class: I

- Z-axis: Motorized

- Workpiece height: max 35 - 37,5 cm

Luxmark M-TOP 200 CO2

- Laser source: CO2

- Laser class: I

- Z-axis: Motorized

- Workpiece height: max 15,5 cm

Luxmark W15

- Laser source: Fiber | Green | UV | CO2

- Laser class: I

- Z-axis: Motorized

- Number of Pallets: 15

Luxmark W72

- Laser source: Fiber | Green | UV | CO2

- Laser class: I

- Z-axis: Motorized

- Number of pallets: 72