With us, a Laser technology for many applications

Who uses our lasers knows it: the applications that can be found with our laser machines are never finished. Used extensively in the dental, industry and goldsmith sectors, Elettrolaser laser machines are able to satisfy many working areas.

Here's what you can do with an Elettrolaser machine.

In the DENTAL sector

The laser used in the dental industry is a security for the dentist and his patients.

Unlike brazing, laser welding achieves a joint that is always the same and homogeneous, mechanically resistant over time, an important added value for the patient.

Compared to traditional brazing, laser welding saves up to 80% of time, as well as greater simplicity and speed.

Laser welding proves to be qualitatively superior in any laboratory situation, from simple repair to the most complex structure, also thanks to the easy setting of the welding parameters on the machine, fine for the expert user and also for the novice user.

With the laser you can weld very thin structures (even less than 0.2 mm thick) thanks to the precise dosage of the applied energy: this is impossible with the other welding systems, excluding the possibility of particular works such as the lengthening of the edge of a crown.

Most welding works can be performed, in comparison to other methods, in a fraction of a second.

The use of lasers in narrow interdental spaces (even in the presence of ceramic coatings) is possible, other systems do not allow it: the minimum diameter of the laser welding point is approx. 0.3 mm, with the other systems is approx. 1.5 mm.

The spot diameter of the laser beam can be adjusted between 0.2 mm and 2.0 mm.

In this way the whole range of interventions that can be carried out in dental technology is covered, from fine welding to finishing of surfaces, for example:

- Laser welding in general;

- Coronal extensions of manufactured articles with and without aesthetic coverings;

- Restoration of the functionality of existing products (sealing of cracks to remove bridges and crowns, closing occlusal holes, restoring centric contacts on metal bites and other);

- Restoration of friction and stability of existing skeletons (combined prosthesis);

- Restoration of the functionality of metal attachments (in cases where the brand and / or provenance is unknown or when the counterpart cemented in the oral cavity is deformed);

- Welded fusions, on prefabricated abutments or on any other metallic artefact;

- Modify artifacts.

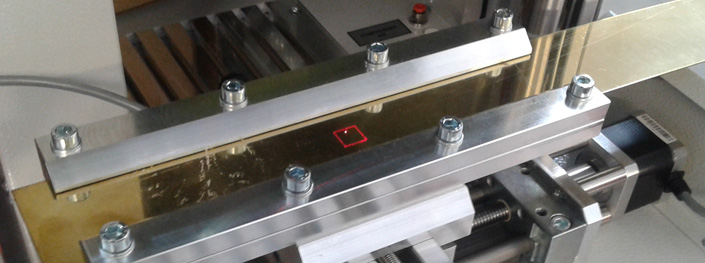

In the INDUSTRY sector

The electric arc welding process played a major role during the last century, replacing the torch technique.

Since the 60s there has been the advent of welding under gas, which has survived for decades in the industry and further developed with the wire electrode.

Machining, productivity, business needs have led the welding technology to evolve again, up to today with the use of lasers.

With spot laser welding, thin sheets can be joined practically without deformation: if the welding points follow each other and overlap, a 'welding seam' is obtained with minimum deformation.

The evolution of laser sources is an exciting story.

Laser welding allows to obtain excellent results in the industrial sector, both for reduced times and for the absolute precision of machining.

The repair of the molds is one of the most famous applications for our lasers: Alpacca, Monel, Titanium, Gold, Silver, Bronze, Copper-Beryllium, Carbon or Stainless steels, aluminum alloys and many other metals are perfectly engraved by the laser beam of our machines.

In particular, applications for mold repair can be:

- Shooting wear on small molds;

- Automatic welding of preset routes;

- Shooting worn edges;

- Filling of grooves and cables;

- Repair of various kinds of micromechanical details;

- Welding of elements with use of filler material.

In the JEWELRY sector

Repairs of jewelry, repairs of watches and glasses, micro-welding: to do all this you need to use a reliable welding machine, which performs the machining with high precision.

That's why the jewelry industry is turning to the laser as a welding method, to make repairs short and to make operations with a much better result.

Repairing jewelry without removing precious stones during processing is a big step forward in the sector and allows you to obtain a product that does not show the signs of the work performed and therefore retains all of its initial value.

The marking on jewels is another fundamental part in the jewelery industry, processing that our laser marking machines successfully deal with:

- Engravings on rings, bracelets, medals, flat surfaces;

- Engraving names, drawings and logos;

- Engraving of trademarks with the relative version for trademarks;

- Engraving on dials of watches and glasses of any metallic material.

After the theory, we just have to show you our practice!

In this 2018 our program of events in the world is varied and complete, reach us on the occasion you prefer!

Take a look at all the scheduled events: Elettrolaser's main events.