Our lasers change their skin: a new design for ever more performing machines

Laser technology has been widespread, for many decades now, in a huge variety of fields, and its success is closely linked to its efficiency and accuracy.

In fact, the laser is a versatile tool, which allows extremely precise results to be obtained quickly. These characteristics have allowed laser technology to revolutionize countless sectors, industrial and not only (just think, in this regard, of the infinite applications of lasers in the medical and biomedical fields and the great advantages they entail in terms of safety and reduction of patient recovery times).

In the field of welding and marking, the laser allows you to work objects made of a large variety of materials, obtaining very precise results in much shorter times than would be necessary if alternative technologies were used. Precisely for this reason the laser is increasingly widespread not only in artisanal contexts but also within industrial plants, since a welding machine or a laser marking machine allows to process a large quantity of pieces per minute, maintaining an always high and constant level of quality.

The lasers currently in our possession allow us to obtain extremely satisfactory performances, but this does not mean that there cannot be further evolutions and updates in this area: the Elettrolaser Research and Development sector works constantly to improve and enhance our lasers, with the aim of making them more and more efficient, safe, reliable and user friendly.

-min.jpg?width=320&name=MEGA%205%20(2)-min.jpg)

-min.jpg?width=320&name=MEGA%206%20(3)-min.jpg)

-min.jpg?width=320&name=MEGA%205%20(4)-min.jpg)

-min.jpg?width=320&name=MEGA%206%20(2)-min.jpg)

The new design of Elettrolaser lasers: all the news

Elettrolaser does not just provide customers with the machines they need to complete their work, but offers a training, support and consultancy service which lasts over time and which allows us, over the years, to create solid and continuous relationships, based on mutual trust and the exchange of ideas and opinions.

Starting from customer feedback and observations, our Research and Development department has studied a series of new solutions that allow us today to offer more energy efficient lasers equipped with improved and more performing capacitors, bars and lamps.

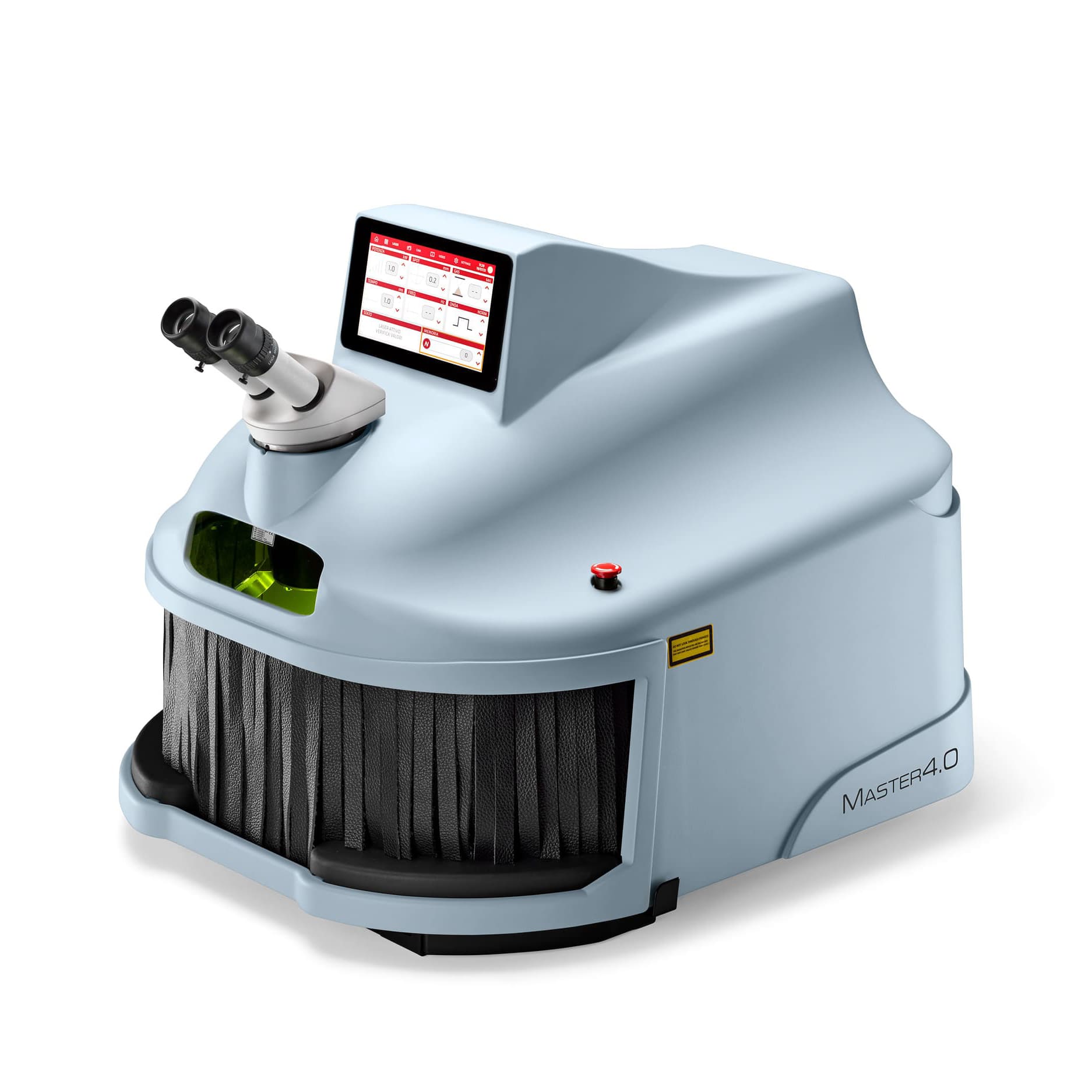

The changes we have implemented, however, are not limited to this: we have worked specifically on the design of our most powerful laser welders (such as the Master 4.0, Mega 5.0 and Mega 6.0 models), with the aim of making the body of the laser more resistant and at the same time more comfortable, also thanks to the insertion of special drawers and armrests incorporated directly on the machine. In this way the lasers are more practical to use.

The restyling also involved the design of the laser opening mouth, which was enlarged to make access to the welding chamber easier both in the case of particularly bulky objects, and in the case in which it is necessary to insert products inside using tweezers.

In this way we can offer our customers more efficient, less energy-consuming, aesthetically more beautiful tools and, at the same time, more comfortable and practical to use, to put all those who use them in a position to operate at their best.