How to choose the welding machine or laser marking machine that best suits your needs

The purchase of a welding machine or a laser marking machine can be a significant stimulus for the growth of large or small companies, but also for many artisans who want to expand their offer and improve the services they offer to their customers.

Choosing a machine that suits your needs is essential to be able to derive the maximum benefit from using a laser: let's find out together what the potential of these tools are and what evaluations to make to identify the best laser marking machine or welding machine for your production activity.

Why choose the laser: all the advantages of an increasingly performing technology

The use of lasers is increasingly widespread in a great variety of industrial fields. This technology, born around the mid-sixties and constantly expanding since the seventies, has undergone constant development over time, which has led to a significant increase in performance and the possibility of obtaining more and more accurate results.

The improvement in technology has also made it possible to make the laser increasingly easier to use: the machines available today exploit fully automated mechanisms, which allow excellent results to be obtained with a minimum investment of time and resources.

The reasons for choosing a tool of this type are innumerable:

The reasons for choosing a tool of this type are innumerable:

- Precision: the laser is a tool that allows you to obtain impeccable results, since it acts in a specific way on very small parts of the object being treated. The laser action spot covers a range from 0.2 mm to 2 mm, and unlike other technologies for metal cutting or welding (such as microflame or arc welding) the use of this tool allows you to act in punctual way, without heating the whole object

- Accuracy: thanks to the great precision of the instrument, the interventions performed with the laser are imperceptible to the eye and therefore guarantee impeccable results

- Versatility: the laser allows you to weld or engrave even very small and very thin elements, always guaranteeing a perfect result from an aesthetic and functional point of view

- Flexibility: the laser can be used for the processing of a large amount of metals, therefore it finds application in many production sectors

- Speed: the time required to complete a laser cutting, welding or marking operation is extremely reduced. This allows you to operate quickly - without compromising in any way the accuracy and precision of the result - and to quickly reduce the costs of purchasing and installing the instrumentation

- Safety: an object treated with the laser is not subjected to trauma of any kind, does not undergo deformations and is not heated

- Savings: the laser consumes a very limited amount of energy, does not necessarily require large spaces and therefore can also be used in small artisan workshops

- Innovation: the laser allows to expand the possibilities of design, making possible interventions that could not be completed using other technologies.

How to choose the welding machine that best suits your needs

To find the right type of welding machine for your business, it is important to consider some fundamental parameters.

First of all, it is necessary to take into consideration the types of material that will have to be treated: the laser, in fact, can be used on a large variety of alloys and metals, including precious ones, and determine which objects will be treated and which processes will be completed is essential in order to identify the machine with the most suitable characteristics.

Another extremely important element to take into consideration is the frequency of use of the laser welding machine, since obviously a laser that is used occasionally for manual processing on single pieces must have different characteristics than those of an instrument that operates continuously. The production volumes are equally significant: machines such as the Master S, Mega HIT, Mega Silver welders are dedicated to those who carry out large-scale operations, while a compact and versatile welding machine such as DaDo is perfect to be used even in a small shop, with a minimum initial investment but great potential in terms of accuracy of the result and efficiency.![]()

Laser marking machines: how they work and how to choose the most suitable one

The laser can be used not only for welding, but also as a tool to remove metal. In this way it is possible to carry out a large amount of processing, ranging from engraving and marking to cutting.

The engraving activities are traditionally carried out by scratching or with tool pantographs, but laser marking allows to obtain extremely more precise results, opening the way to the possibility of making very small but very detailed engravings. With the laser, moreover, it is possible to engrave in points otherwise impossible to reach, and this allows to make precise incisions even in extremely thin or delicate areas (earrings pins, thin components of pendants and other jewelry, as well as internal and external rings).

Generally a laser marker can be used for processing all metallic materials (and some plastic materials), so also in this case it is important to define first the type of material on which you will work and, immediately after, production volumes - and therefore the number of pieces produced per hour - of the company.

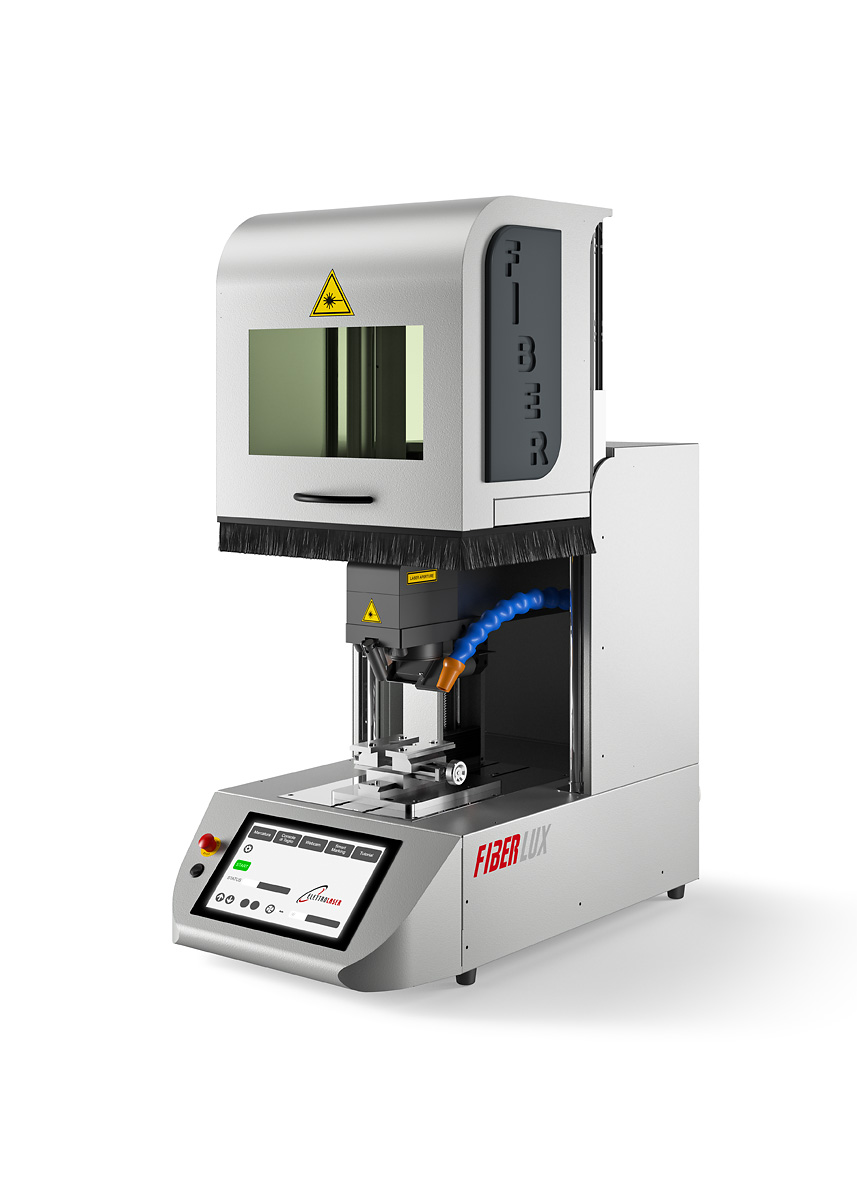

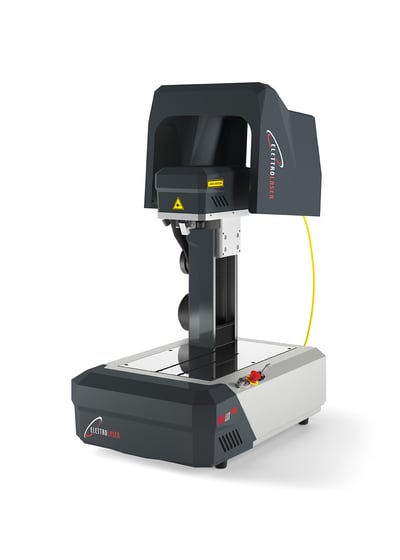

Once these aspects have been established, the next step is to determine the power of the marking machine: a compact machine such as the Fiberlux Nano marker is an excellent starting point to get to know and use the laser and allows you to get closer, over time, to increasingly powerful machine, such as Fiberlux 3D or Fiberlux EL.

When choosing a laser marking machine, it is also important to take into account another parameter: the use of tools of this type almost always requires operator training, since the machine operates through software that requires a certain amount of competence. An evaluation of the actual ease of use of the machine and its software is essential to choose the right marking machine, and it is also for this reason that Elettrolaser markers use programs designed to be as intuitive and flexible as possible, which allow you to acquire the project files in a large variety of formats and which simplify the operator's task to the maximum.