Elettrolaser has been investing since many years in the research and development of its laser welding machines. We have developed a technology that allows the user to weld with excellent and unreachable quality by the other laser welders present nowadays on the market.

The innovative SMOOTH SPOT technology has arrived!

The first feature that distinguishes the new Made in Italy by Elettrolaser laser beam is surely the accuracy and the real shot diameter achieved. The other machines currently on the market miss the diameter shown on the display. This is mainly due to the necessity to get a soft shot but at the expense of precision. Therefore, it is easy to see then that values as 0.2 or 0.3mm, actually when measured are much larger.

Another benefit offered by our SMOOTH SPOT is definitely the energy distribution uniformity and consequent homogeneity of laser welding.

This can be traced back to the laboratory tests we have carried out and reported below.

Fig.1 - Example of a competitor laser shot with too much concentration in the center. Consequences: not perfect material spreading and risk of tearing the metal and the precious object.

Fig.2 - Example of a competitor laser shot with more distributed but insufficient concentration.

Consequences: not perfect spreading of the material to the periphery of the shot and risk of poor sealing of the weld.

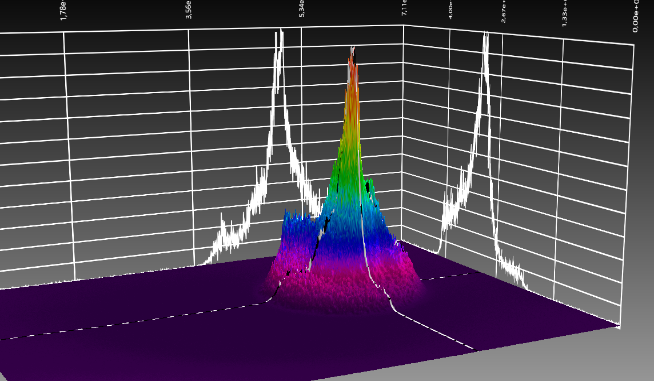

Fig.3 - Example of laser shot with SMOOTH SPOT technology

As you can see, the result is a uniform and well-distributed shot. Therefore, it is easy to guess how a shot with these features gives you the following benefits:

- Improved material spreading

- Uniform sealing welding

- Correct spot size

- Improved surface finishing

- No problems with porosity and holes

Today you can find this technology in our MEGA-SILVER and MASTER-S 130J models.