The use of laser equipment allows for excellent performance in welding precious metals thanks to the extreme precision, speed, and high safety margins that characterize laser technology.

These features prove to be successful even in very specific contexts, such as watchmaking, as demonstrated by the experience of Davide Baraldi, a watchmaker based in La Spezia who has been using an Electrolaser welder in his workshop for some time and also utilizes these tools in the training courses he conducts at the Wostep Foundation.

Baraldi Orologi and the application of lasers in the watchmaking industry

The introduction of the first laser into the Baraldi Orologi workshop dates back over twelve years ago when Davide Baraldi, after discussing with some colleagues who had been using Electrolaser equipment for some time, contacted our technicians. Thanks to his in-depth knowledge of the industry, he had a clear idea of the advantages that lasers could provide to his business and was therefore seeking a welder model that could combine reliability, efficiency, and precision.

At that time, his choice fell on the Master 100 welder, which he has been continuously using until recently when he decided to upgrade to the Master 4.0 model.

%20(1)-1.jpg)

%20(1)%20(1)-1.jpg)

"The first laser I purchased was the Master 100, and a year ago, I upgraded to the Master 4.0. These machines have the right power and the right price-performance ratio, and they are reliable and efficient."

The use of such tools proves to be particularly useful in the day-to-day experience of a jewelry workshop because it allows for the quick repair of dents and other minor damages to the watch case and/or bracelet. It also enables more complex operations, such as the complete restoration of watches worn down by previous polishing. The use of lasers is successful not only because it makes these types of interventions easier and faster but also due to the aesthetic results it achieves. By using a laser welder, it is possible to work on various materials that make up the watch (gold, platinum, steel, etc.) without using alloys but by adding small amounts of the same metal, ensuring perfect color uniformity and a homogeneous outcome. Thanks to the laser, a wide range of interventions, ranging from complete watch restoration to small but essential repairs, can be carried out safely. This has allowed Baraldi Orologi to expand its services to customers, offering new services that would be impossible to provide without the use of such equipment.

The services of Electrolaser and the experience at the Wostep Foundation

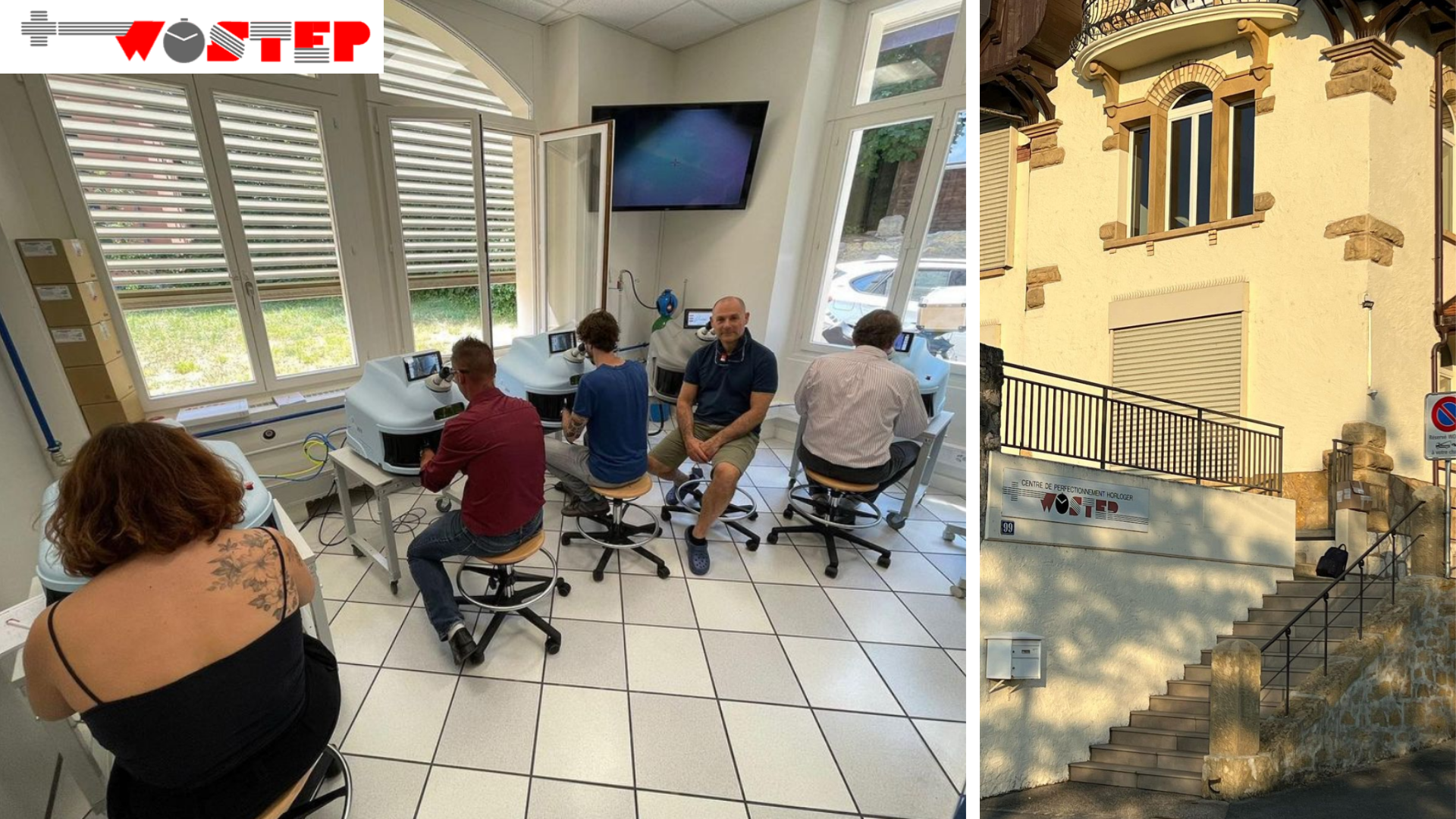

The relationship between Electrolaser and Baraldi Orologi has developed over time into a true collaboration, thanks in part to the ability of Electrolaser technicians to promptly respond to any needs (https://www.elettrolaser.com/it/blog/consulenza-installazione-training-e-supporto-tecnico-i-servizi-elettrolaser-accompagnano-la-crescita-del-tuo-business) and solve problems in a timely manner. In addition to the reliability and user-friendly nature of the lasers, this has prompted Davide Baraldi to recommend Electrolaser welders to the Wostep Foundation in Neuchâtel, a specialized foundation for the training and development of watchmakers that represents a global reference point for the industry.

Wostep is the first internationally recognized institution to offer a one-week course specifically dedicated to the use of lasers for watch restoration and aesthetic refurbishment, taught by Davide Baraldi himself.

During the training week, students are introduced to the theory and practice of restoration and familiarize themselves with the operation of laser welders. They learn how to optimize the tool's settings based on the specific task at hand. The course then proceeds to teach students the techniques for correctly applying additional material, so as not to produce defects on the watch, and for achieving polishing or satin finishing that restores the watch to its original state.

To illustrate all these types of work, five Electrolaser welders are used in the context of the Wostep course (four Master 4.0 and one Mega 5.0).

-1.jpg)

%20(1)-1.jpg)

The ease of use, reliability, and precision of these tools make them particularly suitable for use in a training course, where students need to become familiar with the equipment and easily understand how to use it. The Mega 5.0 model, in particular, is very convenient as it allows the actions performed by the instructor to be projected onto a large screen using the HDMI output, enabling course participants to observe the various techniques and procedures in real-time.

The results achieved so far have been extremely satisfying, and the collaboration between Baraldi Orologi, Wostep, and Electrolaser proves to be particularly fruitful and positive, not only for those who already know and master laser usage but also for those approaching this technology for the first time.

If you want to learn more about Electrolaser welders and their potential applications in the field of jewelry and watchmaking, please contact us!